PRESSURE

Manufactured in accordance with latest international Standard EN-837, Pressure and Differential Pressure gauges are manufactured at our New Mumbai plant, established under technical collaboration with M/s. Gauges Bourdon Ltd. – France. High quality gauges are proven for its precision, reliability, safety and high product life cycle in worldwide onshore and offshore industries.

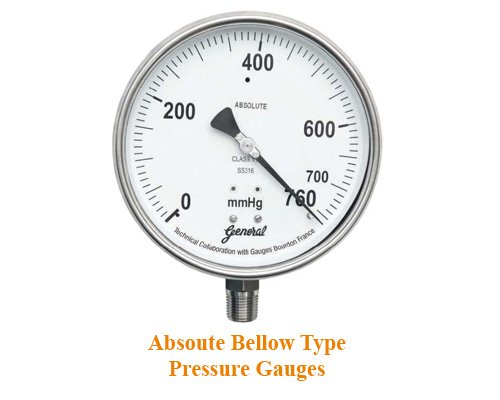

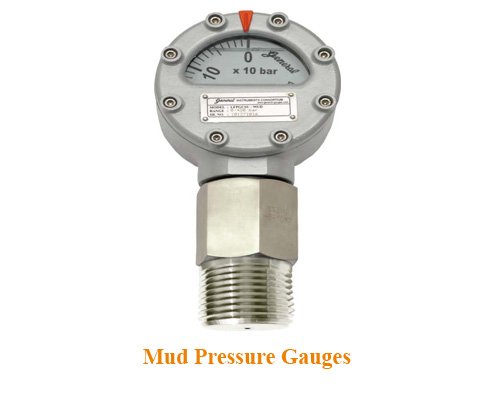

Pressure Gauges Types: Variety of models based on sensing elements such as Bourdon, diaphragm, Capsule, etc. are available as well as special gauges such as Absolute Pressure Gauges, Master / Test Gauges, Mud Gauges, Solid front Case, liquid (Glycerin / Silicon filled) gauges, Receiver gauges, hygiene / sanitary gauges, etc. are available.

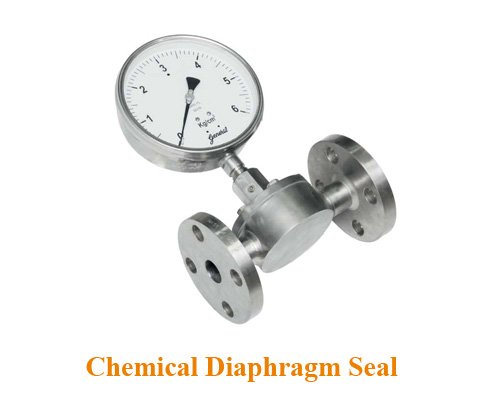

Diaphragm Seals: Diaphragm Seals are available in various designs such as flush diaphragm seal, Sandwich type “I” section diaphragm seal, Pan cake type diaphragm seal, in-line type diaphragm seal, jacketed type in-line diaphragm seal, extended type diaphragm seal, Capillary type diaphragm seal, etc.

For high temperature applications diaphragm seal are provided with Silicon oil grade DC 200, DC 704, DC 705, DC 710 etc and based on specific request Fluorolube oil, glycerin, halocarbon oil, food grade vegetable oil is also provided.

Range: Pressure Gauges designed from pressure range Vacuum (-) 1 to 3000 kg/cm2 ( higher ranges upon request). The latest IP-68 protection is offered as standard feature for all gauges.

Wetted Parts: Available in Phosphorous Bronze, Brass, SS304, SS304L, SS316, SS316L, SS316 Ti, Monel, Hastelloy, Inconel, Incoloy, Titanium, Tantalum, Nickel, PTFE Coated / Lined / block etc.

Accuracy: +/- 1% FSD (standard),+/- 0.5% FSD on request. Test / Master Pressure Gauges are available with accuracy of 0.25% FSD.

Accessories: Gauge Saver, Snubber (Pulsation Dampener), Cooling Tower, Syphon, Gauge adaptor, Swiveling adaptor, Gauge Cock, Needle Valves, Manifold Valve, flushing ring, pointer puller and fixture kit, etc. are available.

Special Features: Maxima pointer, NACE Compliance, Colour band, dual scale range, liquid filed case, O2 (oxygen cleaning), N2 (Nitrogen cleaning), Ammonia gauges, blow out disc at back, vacuum protection, capillary extension, micrometer pointer and many other features.

Unique design of external zero reset Knob for liquid filled Pressure gauges wherein zero can be adjusted without opening the case and bezel and draining the liquid filling from case. This special feature is developed by GIC and essentially demanded by oil and gas / hydrocarbon industry onshore and offshore.

Quality: certified as CE, ATEX, GOST –R, GOST Pattern approval, IBR certification, Type tested by BV, Calibration reports from NABL (National Accreditation Board for Testing & Calibration Laboratory) certified in-house calibration laboratory. Regular Inspection and testing by BV, DNV, TUV, Lloyds, ABS, Moody, EIL, CEIL, etc.

Certificates: Certificate of conformance, Test and calibration certificate, IP Certification, Material test certificates, 3.1 MTC, 3.2 MTC, PMI, PWHT, IGC various practices, NACE-MR-01-75 & NACE-MR-0103, Hydrotest, etc. available.

Pressure Gauges